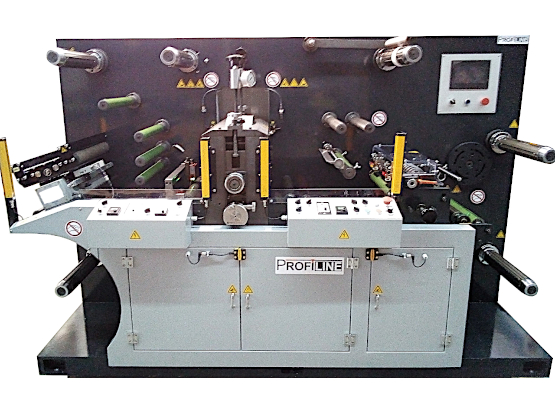

Semi-rotary punching machine PROFIline R-320

The semi-rotary die-cutting machine PROFIline R-320 enables the register-accurate production of die-cut parts and labels as well as narrow-cut rolls from any roll materials such as paper, films, adhesive labels and laminates up to 600 g/m². It assembles and controls web-shaped materials up to a width of 320 mm.

Made from a solid steel frame, the robust machine is easy to operate after just a short training period. The speed can be controlled electronically. The machine stops automatically once a preset number of labels or running meters has been reached.

The simple, efficient design of the system enables extremely short set-up and changeover times.

Material to be processed: Adhesive labels, paper, film and laminates up to 600 g/m²

Features of the PROFIline R-320

Steel plate construction

-

Welded steel frame

-

Sides and cover plates made of sheet steel

-

Electronics integrated in the machine housing

-

Connection 400 Volt

Unwinding with pneumatic expansion shaft

-

Magnetic particle brake

-

Right/left unwinding possible

-

Automatic train control

-

Shutdown at end of roll

-

Pneumatic expansion shaft 76 mm

-

Diameter max. Ø 600 mm

-

Max. castor weight 120 kg

-

Material width 100 mm to 320 mm

Web edge control

-

Swivel frame guide

-

Electromotive actuator

-

Max. Web position error +/- 10 mm

-

Infrared edge sensor

-

(Ultrasonic edge sensor on request)

Splice table

-

Integrated in web guiding system

-

Two mechanical clamps

-

Blade guide for cross or diagonal cut

Semi-rotary die cutter

-

Die-cutting length semi-rotary 200mm-450mm

-

Die-cutting length fully rotary 250mm-550mm

-

Trio motion control system

-

Servomotor-driven

-

Optical register sensor by print mark or label

-

160 teeth magnetic die-cut cylinder

-

1/8 inch cp toothing

-

Counter cylinder

-

Pressure bridge with pressure bearings and wiper felts

-

Hydraulic die-cutting pressure indicator

-

Adjustable fume cupboard with magnetic particle clutch and 3 inch expansion shaft

-

Without die-cutting tools

Laminating station

-

Unwinding with pneumatic expansion shaft 76 mm

-

Manually adjustable magnetic particle brake

-

Rubberized pressure roller

-

Rewinding with pneumatic expansion shaft 76 mm

-

Manually adjustable magnetic particle clutch

Preferred unit

-

Steel roller

-

Rubberized pressure roller

-

Adjustable contact pressure of the pressure roller

-

Servomotor-driven

Slitter

-

Silhouette system

-

Eight upper knives

-

Eight bottom knives

-

Minimum cutting width 18mm

-

(Other cutting systems blade and crush cut on request)

2 pieces Rewind

-

Pneumatic expansion shaft for 3 inch sleeves

-

Web tension adjustable via magnetic powder clutch

-

Inner or outer winding fixed

-

(Switchable on request)

-

Roller diameter max. 600 mm

-

Permissible axle weight 120 kg

Suction device

-

Axial fan for extracting an edge strip

Operating and control unit

-

Colour touch display (operating language English)

-

Main switch

-

Control ON

-

Machine START / STOP

-

Set-up function

-

Emergency stop

-

Variable speed through rotary potentiometer

-

Meter and label counter switchable

-

Automatic stop of the machine when the preselected number of labels is reached

-

Track run from left to right

-

Web speed up to 90 m/min in rotary operation, depending on the product

-

Web speed up to 70 m/min in semi-rotary operation, depending on the product

Technical data

-

Electrical voltage: 400 Volt

-

Frequency: 50 Hz

-

Length x width x height approx.: 4,300 mm x 1,200 mm x 1,800 mm

-

Weight approx.: 3,600 kg