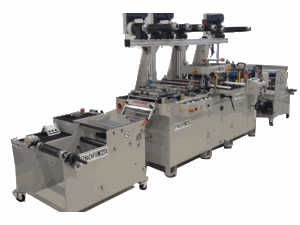

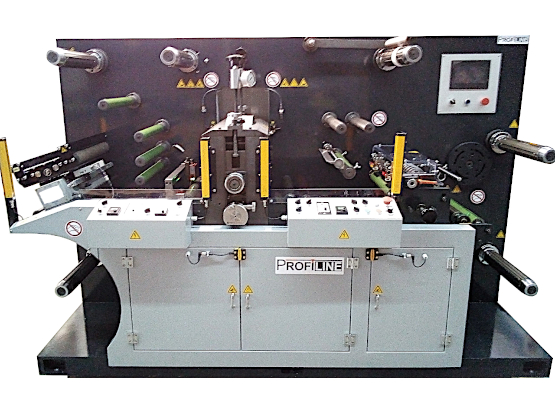

You can choose between flat die-cutting and rotary die-cutting , with or without a cutting unit, with or without a laminating station.

Die-cutting machines are used in many industrial sectors. Primarily in the label industry, where countless self-adhesive films, fabrics and composite materials are processed into decorative, sealing or labeling die-cut parts. However, stroke and rotary die-cutters are also used in leather processing, tarpaulin production, advertising and electrotechnical applications.

The automatic die-cutting presses offered by CMC Maschinenbau differ from each other by several important features:

-

Maximum possible die-cutting format

-

die-cutting process

-

die-cutting speed

-

Maximum die-cutting pressure/height

-

Number of die-cutting heads

Comparison of stroke die-cutting vers. Rotary die-cutting vers. laser die-cutting:

All three processes have their specific advantages and disadvantages. It therefore depends on what objective you are pursuing with the purchase of a corresponding die-cutting machine. You can find more information about the advantages and disadvantages of the three die-cutting processes here here.

Due to the wide range of possibilities, we can only present a limited selection of flat die-cutting and rotary die-cutting machines here.