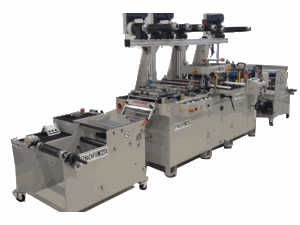

PROFIline F-320A flat die-cutting machine

The PROFIline F-320A flat die-cutting machine enables the production of labels and die-cut parts on rolls or sheets. The flat die-cutter achieves a die-cutting speed of up to 180 strokes/min. Thanks to the 4 rewinders and 4 unwinders, even complicated die-cut part designs are possible.

Material to be processed: Adhesive labels, paper, film, laminates and foams up to 600 g/m²

Please provide samples for die-cutting tests before placing your order.

Features of the PROFIline F-320A

Cast iron construction

-

Machine body made of solid cast iron

-

Covered with lacquered steel plates

-

Sides and cover plates made of sheet steel

-

Electronics integrated in the machine housing

-

Separate unwinding

-

Separate rewinding

-

Connection 400 Volt

Separate unwinding with pneumatic expansion shaft

-

Magnetic particle brake

-

Right/left unwinding possible

-

Dancer position rule

-

Automatic switch-off at the end of the roll

-

Pneumatic expansion shaft 76 mm

-

Diameter max. Ø 700 mm

-

Max. castor weight 240 kg

-

Material width up to 320 mm

Separate unwinding with pneumatic expansion shaft

-

Magnetic particle brake

-

Right/left unwinding possible

-

Advantage due to steel rubber roller

-

Dancer position rule

-

Automatic switch-off at the end of the roll

-

Loop control

-

Pneumatic expansion shaft 76 mm

-

Diameter max. Ø 700 mm

-

Max. castor weight 240 kg

-

Material width up to 320 mm

Track running regulation

-

Manually at the infeed of the main machine

-

Forced alignment of the track by loop control

2 pcs. laminating station

-

Rubberized roller

-

Rotating steel roller

-

Adjustable pressure of the pressure roller

Register regulation

-

Sick print mark reader

-

Presetting the print mark via touch display

-

Register accuracy +/-0.1 mm with print mark 2x5 mm

-

Align the track by adjusting the light sensor and preference setting

Flat punching station

-

Four-column lift punch

-

Die-cutting length up to 350 mm

-

Die-cutting width 300 mm

-

Die-cutting pressure 2.8 tons

-

Suitable for steel strip cuts (12 to 42 mm) or magnetic plate

-

Suitable for complete tools with a maximum height of 65 mm

Aluminum profile bridge

Over the entire length of the main machine

Equipped with :

-

4 Unwinder

-

Switchable right-left run

-

1 grid rewinder for punching waste

-

5 pneumatic expansion shafts

-

Web tension can be adjusted separately via potentiometer

Counter

-

Stroke counter with preselection option and break contact

-

Sheet counter with car breaker

Bow cutter

-

Cutting width 320 mm

-

Cutting length 10-600 mm

-

Length input via the touch screen

-

Storage table

Rewinder and slitter

-

Pneumatic expansion shaft for 3 inch sleeves

-

Web tension adjustable via magnetic powder clutch

-

Roller diameter max. 700 mm

-

Scissor carving

-

Permissible axle weight 240 kg

Operating and control unit

-

Colour touch display (operating language German)

-

Main switch

-

Control ON

-

Machine START / STOP

-

Set-up stroke

-

Switch for one operation

-

Emergency stop

-

Variable speed through rotary potentiometer

-

Meter and label counter switchable

-

Automatic stop of the machine when the preselected number of strokes is reached

-

Electronic components integrated in the machine housing

-

Track run from left to right

-

Speed 20-180 strokes/min

Special maintenance instructions

-

Oil change every 2,000 operating hours, or every 12 months

-

Approx. 8 liters of 10 (15) W40 are required

-

The oil filter must be cleaned monthly

Technical regulations

-

Electrical voltage: 400 Volt

-

Electrical power: 4.8 KW

-

Current: 16 amps

-

Frequency: 50 Hz

-

Main machine L x W x H approx. 2,100 mm x (850 mm) Installation width 950 mm x 1,800 mm

(width of 850 mm can be achieved after dismantling the work platform in front of the punch and control panel)

-

Rewinder: approx. 800 mm x 700 mm x 800 mm

Weight: approx. 200 kg

-

Unwinder: approx. 750 mm x 800 mm x 900 mm

Weight: approx. 200 kg